CONSTANT

INNOVATION

Giuliani has been producing cylinders since 1968 and since then has been constantly striving to improve its products by working alongside customers and finding new technological solutions.

We follow All Customer’s needs starting from the design or co-design phase.

During

the

design or co-design phase we

bring the know-how necessary for the creation of new high-tech and

high-performance products.

We are therefore able to realize the prototyping and follow the customer step by step up to the approval and test phase of new products, carried out according to the specific needs of each customer in an internal department dedicated to homologation tests and R&D, to then continue with the pre-series and industrialization for the mass production phase in our production departments.

Giuliani's

R&D activities include:

• durability and resistance test

• testing in severe environments

• corrosion resistance test

• cylinders integrated with sensors development

• bio oils compatible cylinders development

• innovative sealing solutions development

• new sensors development

• new integrated solutions development

- Design

- Prototyping

- Homologation

- Pre series

- Mass production

MORE

THAN 10

INTERNATIONAL PATENTS

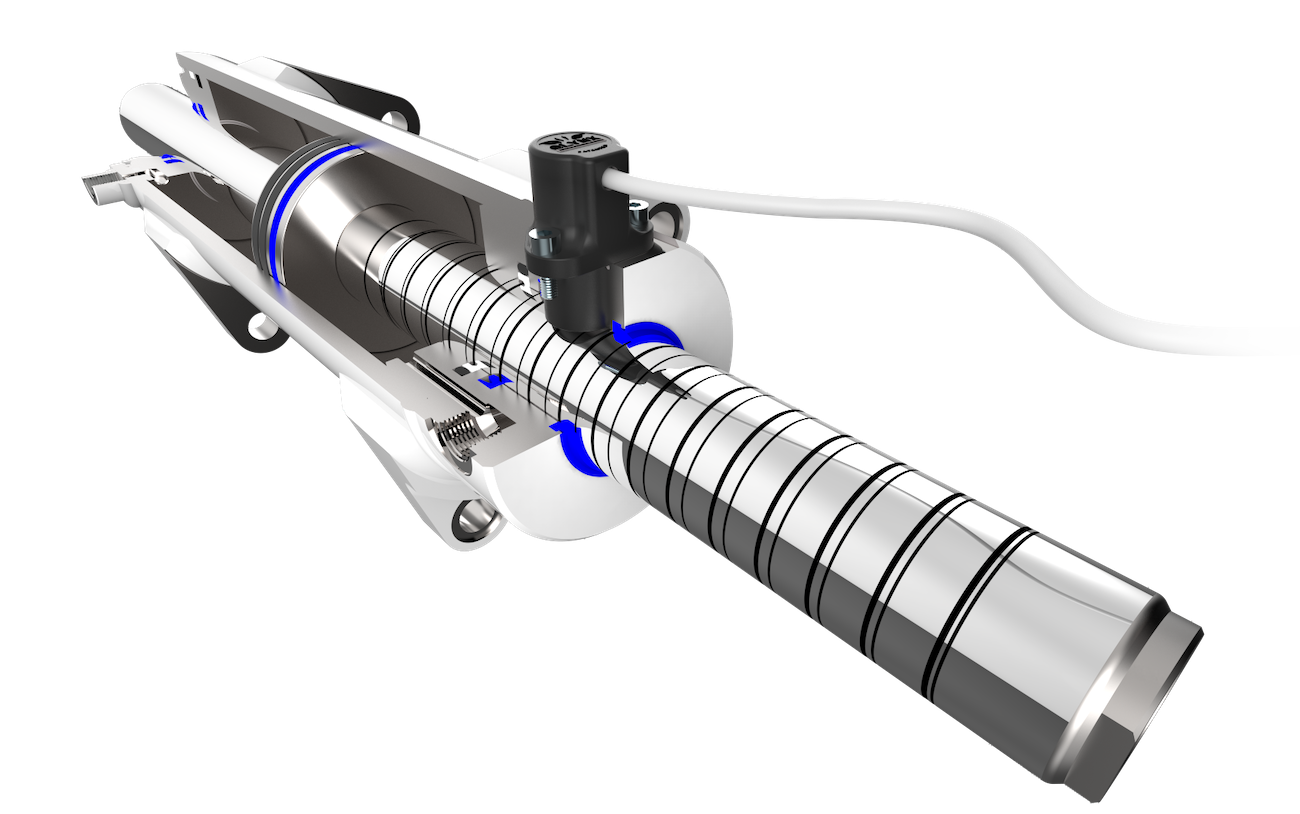

Since the end of the 90s, Giuliani has been working on the research and development of innovative solutions aimed at integrating optical sensors in hydraulic cylinders, to better respond to customer needs and to expectations of the future, becoming a world leader in hydraulic cylinders equipped with integrated optical sensors thanks to the development of eLYNX technology.

Discover our patented eLYNX TechnologyTEST

BENCHES

The

quality of Giuliani products is guaranteed by the homologation tests

that are carried out according to the specifications of each customer

in an internal department dedicated to homologation tests.

Below is

the list of tests that Giuliani is able to perform for the

homologation of its products:

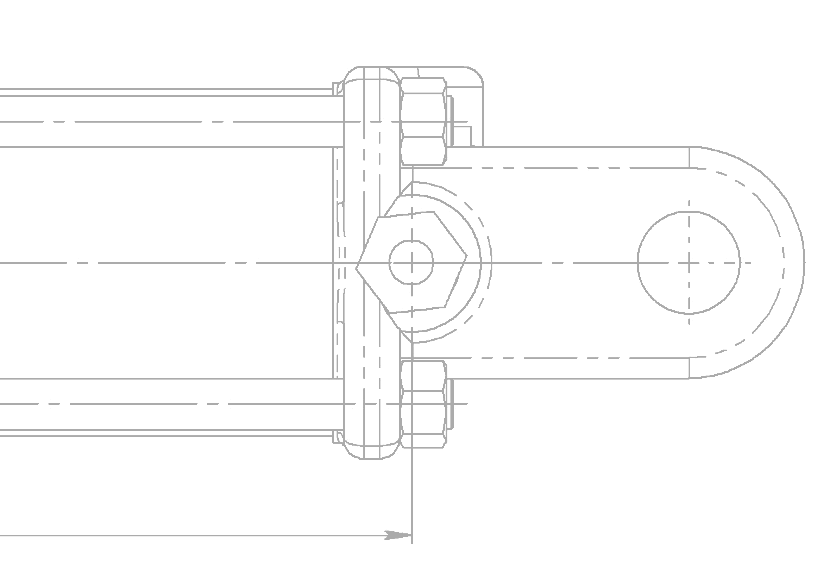

Different test benches able to simulate the life of the hydraulic cylinders in real application conditions, with the possibility, for the steering cylinders, to accurately reproduce the loads applied by the steering geometry or to use the customer's steering axle.

Bench to test the functioning of the cylinder under stress in extreme climatic conditions.

Test bench that reproduces the maximum stresses allowed on the application, tests the mechanical and hydraulic performance of the cylinder in extreme operating conditions.

Test bench to verify the correct operation of the cylinder in a contaminated environment.

Static test bench to test the cylinder at pressures up to 800bar